Backed by leading programs – trusted by the companies we serve.

How it Works

How Deepacks Inspection System Works

Easy to deploy proprietary AI-models specifically for manufacturing.

Step 1 Collect data

Mount the camera and capture as little as 100 images directly from your production line. Deepack learns from real-world variation — including lighting, shape, and recycled material inconsistencies.

Step 2 Annotate

Annotate just 60 examples — or let us assist. The model learns to recognize both known and previously unseen defect types, making your system more adaptable over time.

Step 3 Train The Model

Click “Train Model” and let the system process your images. In around 2 hours, your custom model is ready to run live and sort out defective parts automatically.

Key Features

In-Depth Explanation of Our Features

Production-Ready AI with Built-In Protection for Data, Models, and Operations.

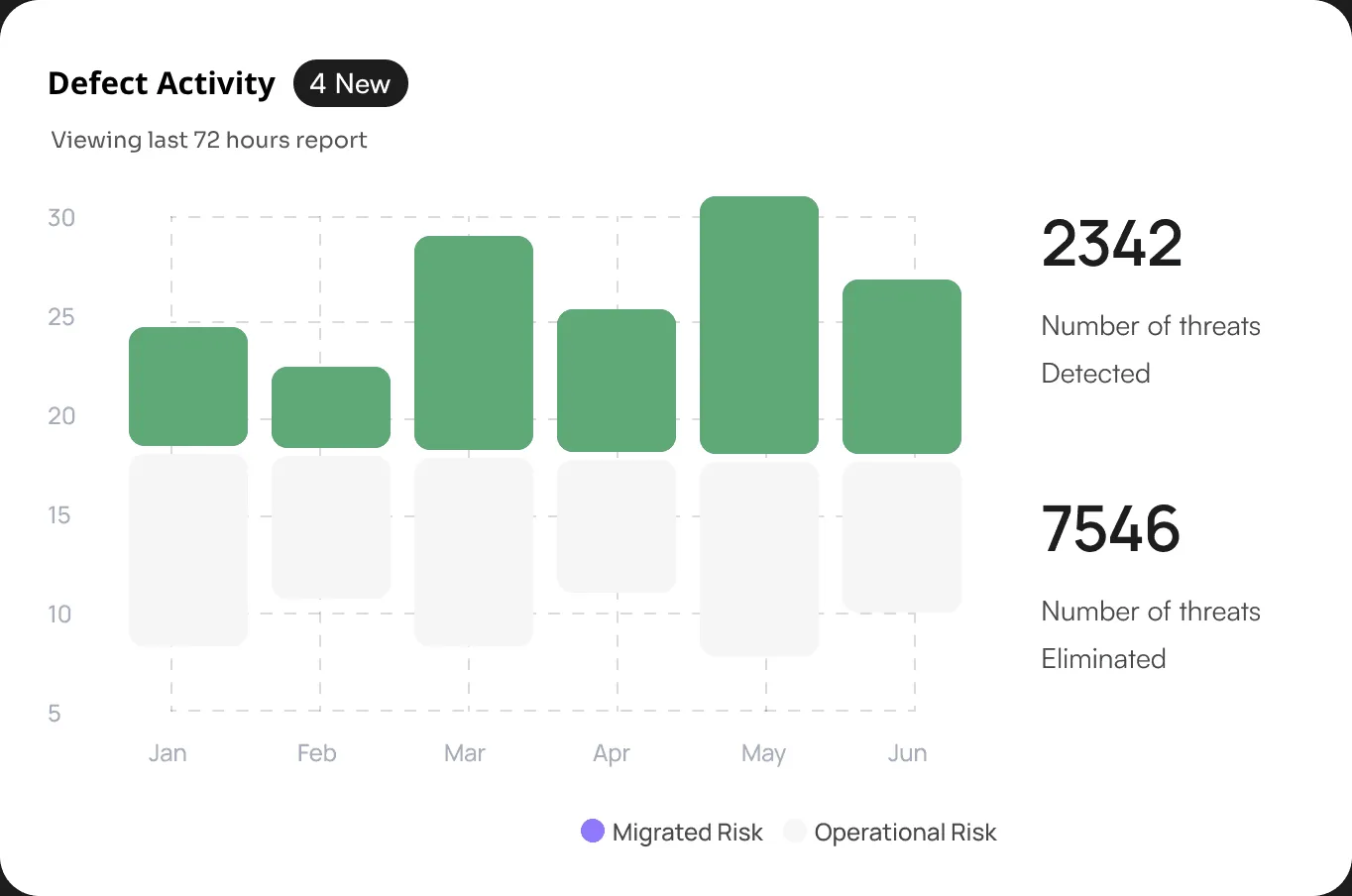

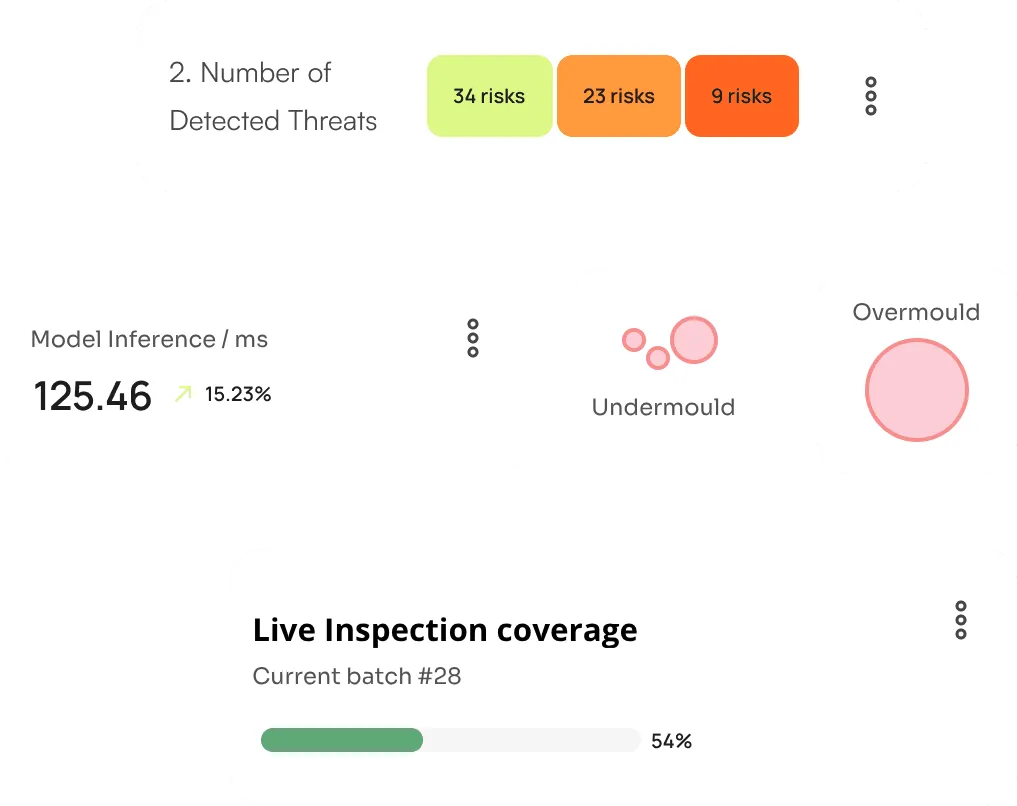

Continuously evaluates potential risks in image data and AI usage

Our system actively analyzes real-time image data to detect production risks before they escalate. This includes identifying patterns like recurring defects and product inconsistencies.

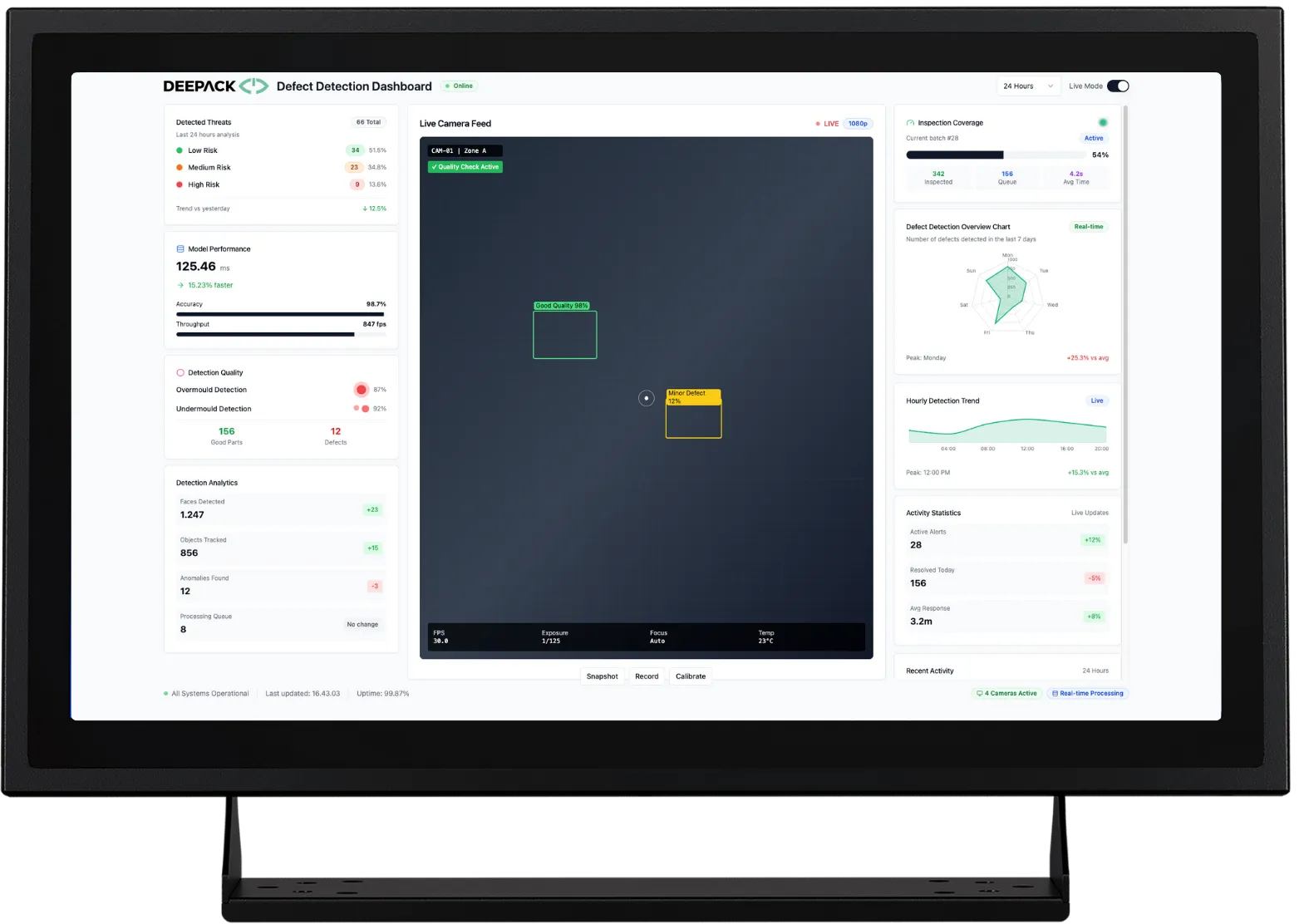

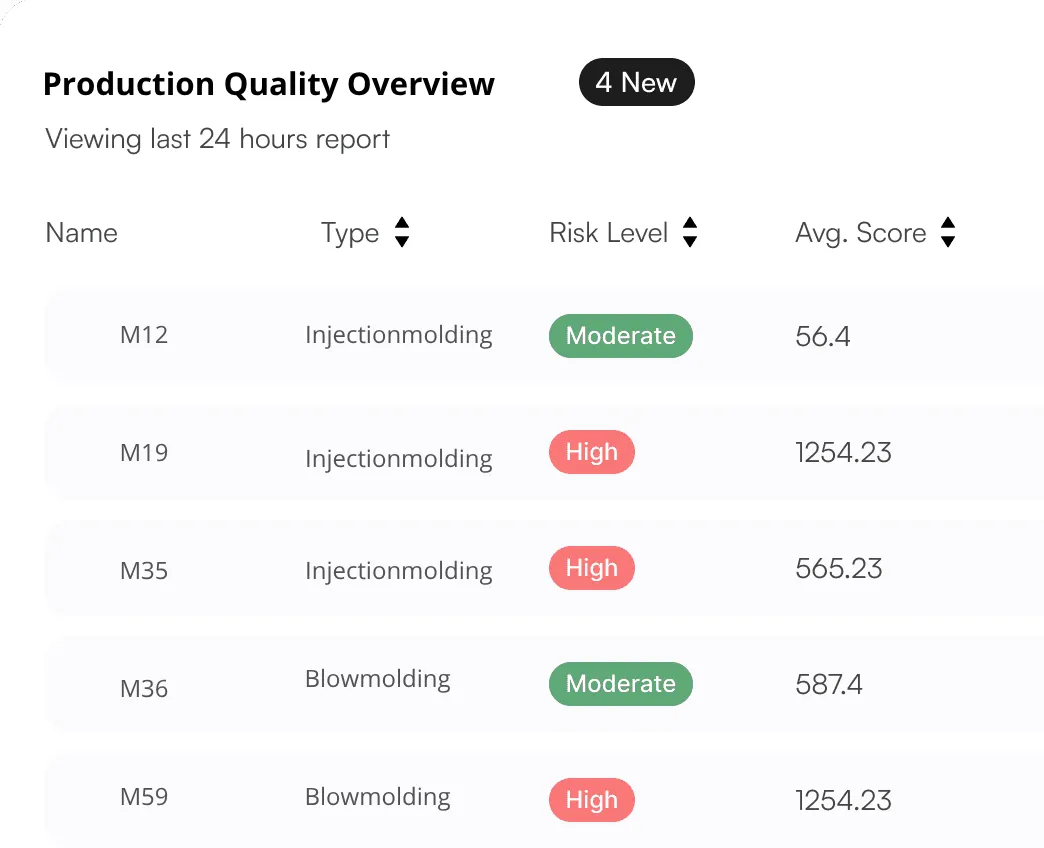

Provides full visibility into production health and risk status

The dashboard gives operators and managers a clear overview of line performance, system alerts, and product quality trends. You can set performance thresholds and get real-time alerts when a deviation occurs — so you can act before scrap or downtime increases.

Logs and Monitors All Inspection Events on the Production Line

Deepack automatically records every inspection event — including what was inspected, the inspection result, and its correlating batch. This creates a complete audit trail that supports quality documentation, traceability, and root cause analysis.

Learn More Details

Essential Feature

What Makes Deepack Stand Out.

Designed for real production, not labs — Deepack makes AI inspection easy to run and easy to trust.

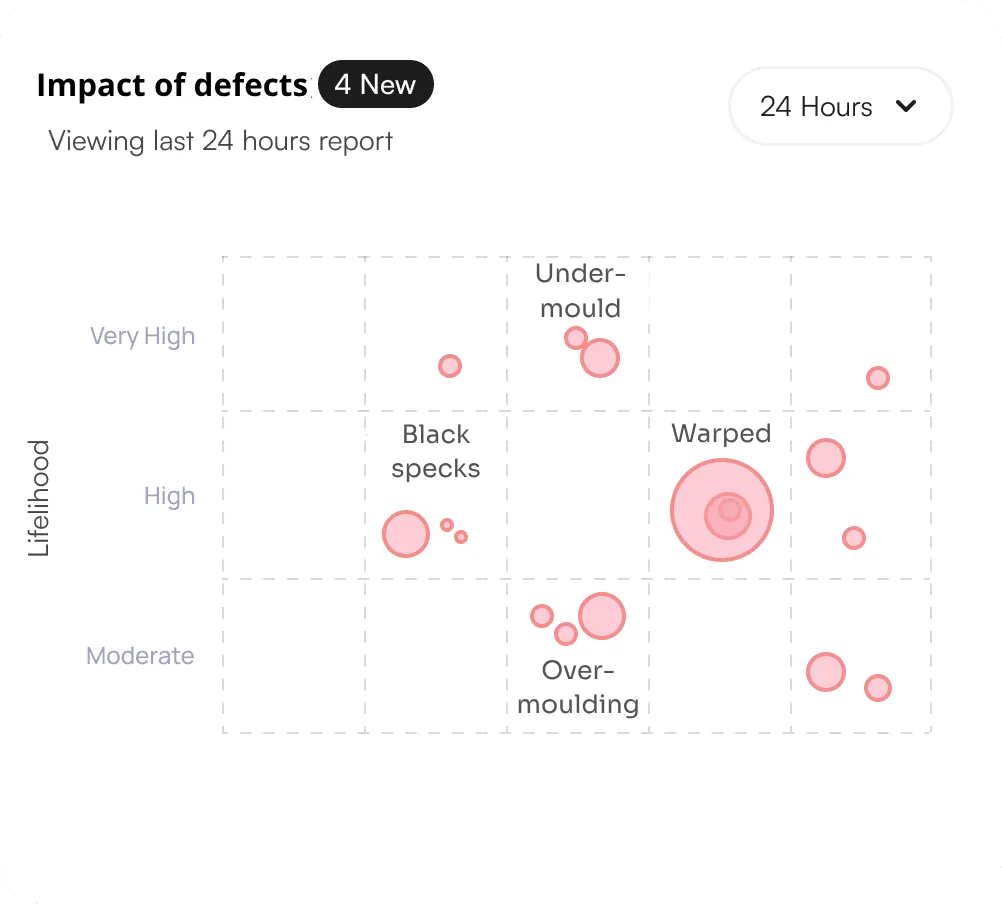

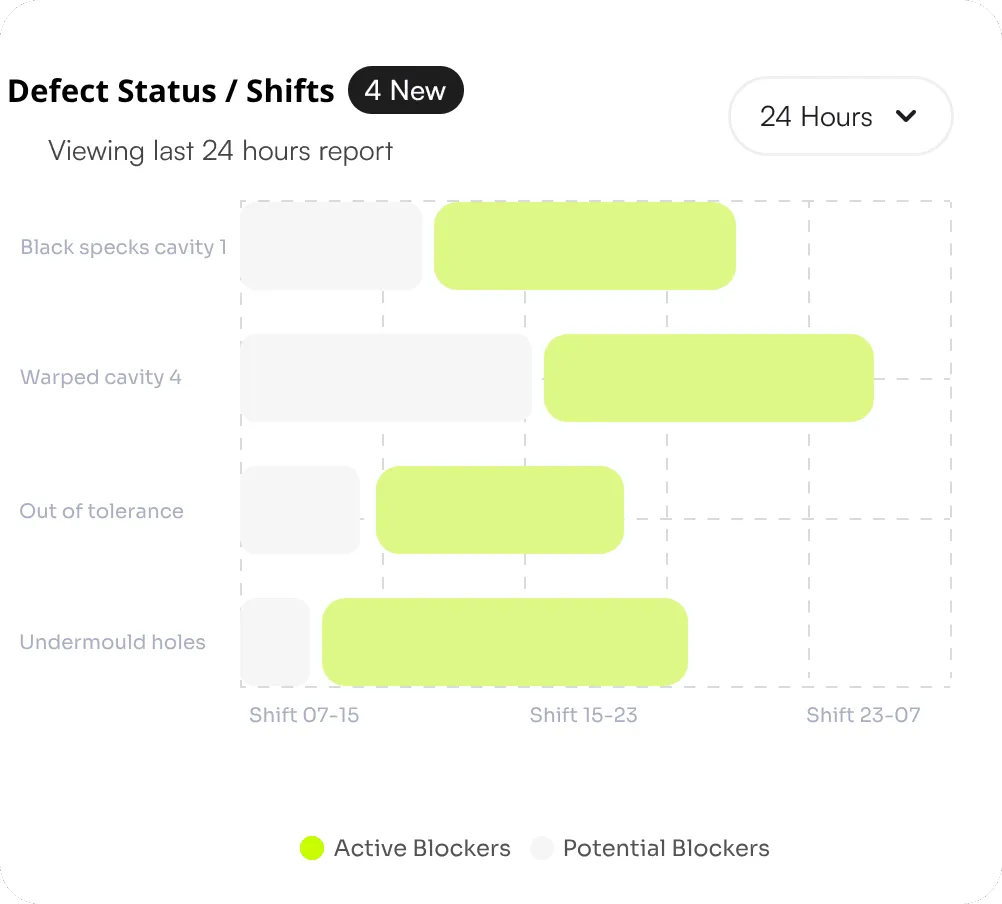

Monitor, analyze and act on quality data

Deepack helps you visualize and track defect trends, product performance, and production issues — all in real time. With actionable insights, you can optimize processes and reduce waste without slowing down your line.

Defect & Trend Logs

Every inspection is logged, giving you a full overview. Ready for internal reporting or customer documentation.

Anomaly Alerts

Get notified if your defect rate spikes. You stay in control — even under changing conditions.

Delivers a complete defect overview.

-

All production data is handled securely — encrypted both in transit and at rest

-

Access is controlled using role-based permissions (RBAC) and two-factor authentication (MFA).

-

We continuously audit system usage to ensure compliance and traceability in quality-critical environments

Features Explained

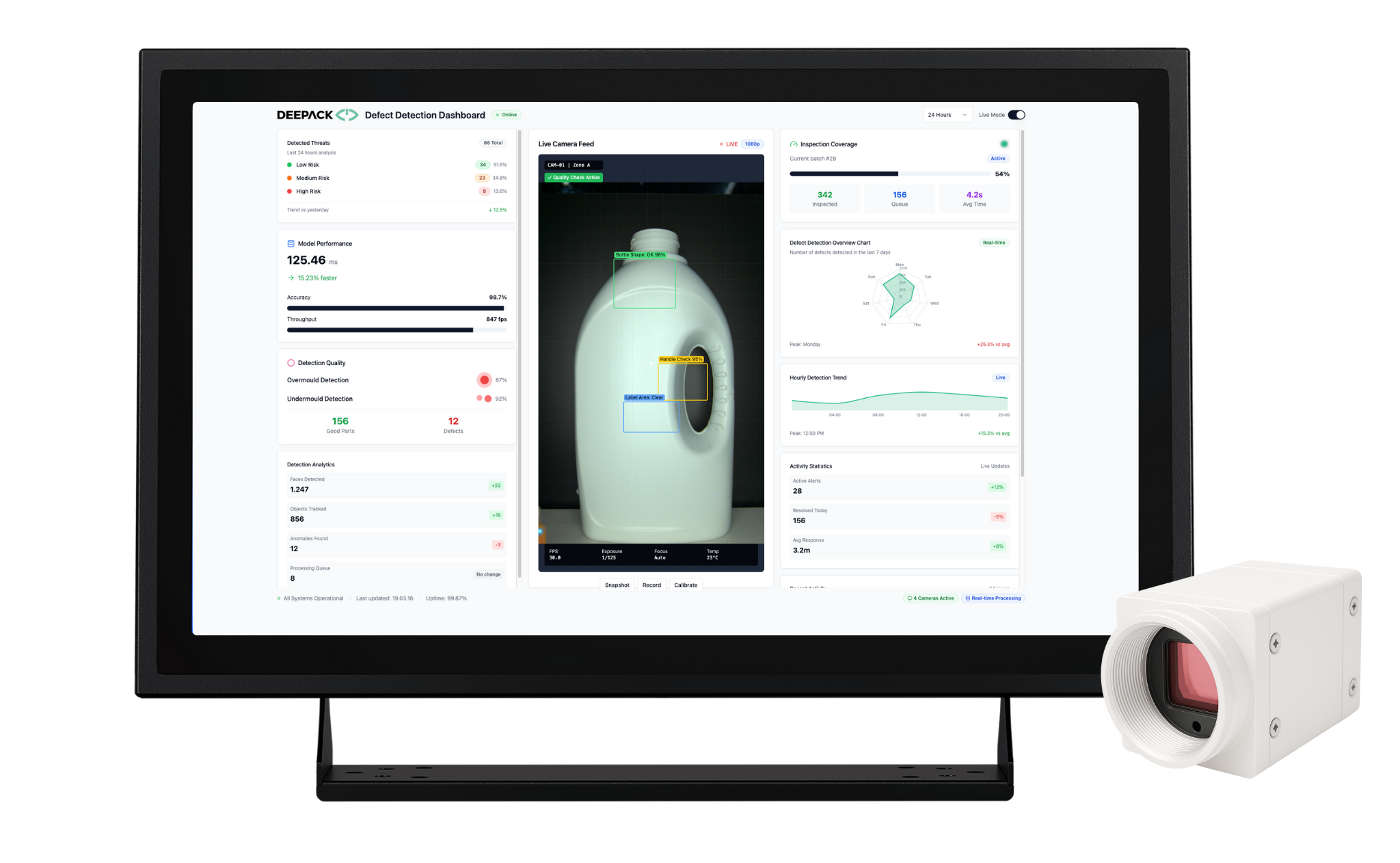

Complete Visionsystem Deploys Fast, and Finds the Unexpected

Deepack delivers a complete plug-and-play inspection system — combining fast-to-train AI with powerful anomaly detection that spots even unseen defects. Designed for real production, not labs.

Hardware & Deployment

Our vision system includes everything you need — camera, software, and interface — pre-configured for your line. Just mount, connect, and go live. No engineers needed. No complex setup.

AI Capabilities

Deepack’s AI learns normal patterns fast and flags outliers — even if the defect has never been seen before. That means better quality control, even with product variation or production with recycled materials.

Production Compliance

Every unit is tracked and logged. Whether for traceability, audits, or customer reporting — Deepack gives you full visibility into inspection performance and product quality.

Defect Escalation

Deepack can trigger I/O signals directly to machinery — stopping production, sorting out defects, or adjusting process parameters in real time. Actions are tailored through operator-defined workflows.

Explore Smarter Quality Control with Deepack

Discover how AI-driven visual inspection can reduce errors, cut costs, and adapt to your production line — without complex setups.

Book a Demo