Changelog

Our Latest Features and Improvements

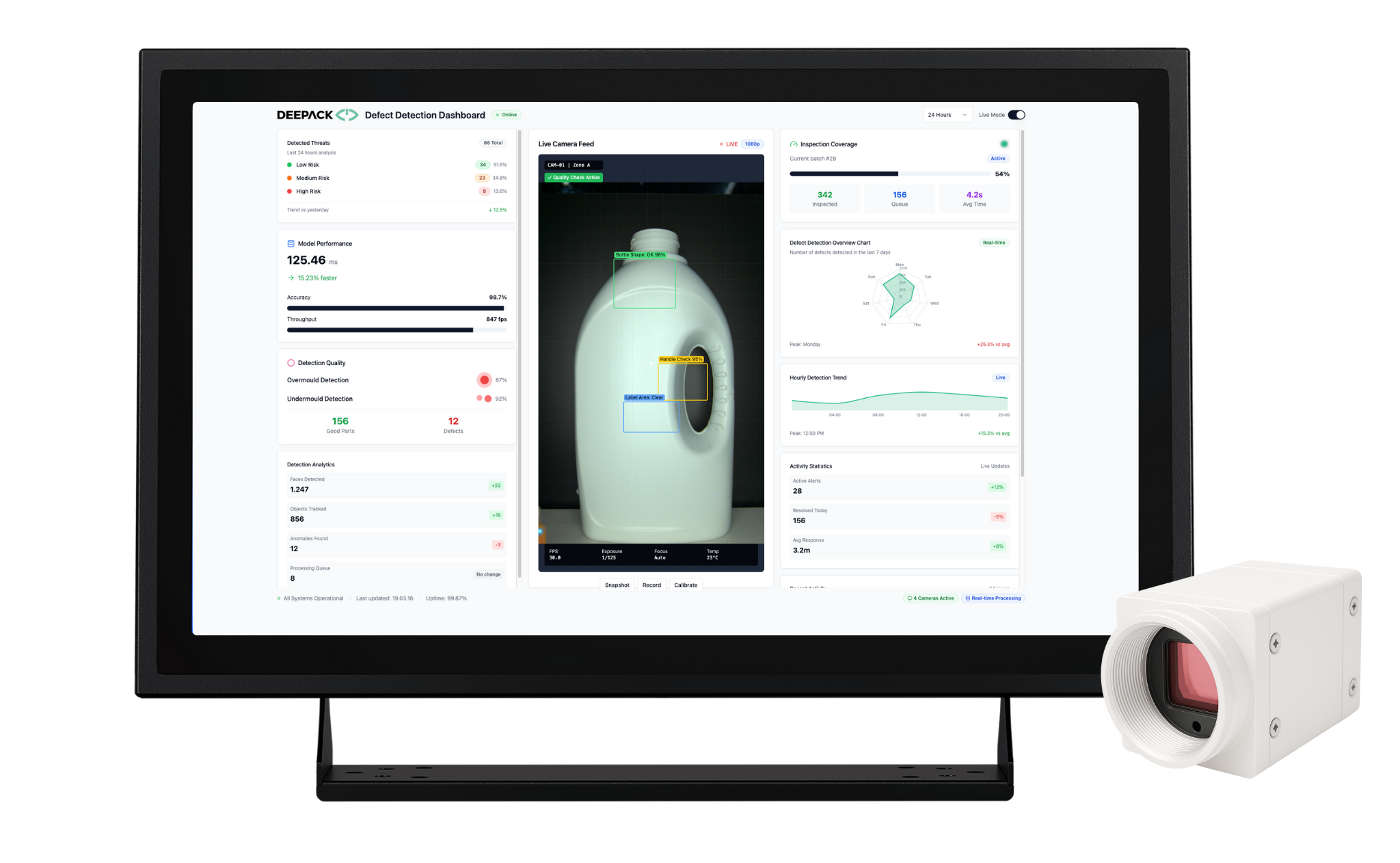

Your Trusted Partner in Simple and Easy to deploy AI Inspection Systems for modern production environments.

A breakthrough in fast, adaptive, and operator-friendly inspection

June 1, 2024

Version 2.0.0

Coming Q3 2025 — Deepack’s Proprietary AI Model for Manufacturing

New Features:

We’re launching our most powerful upgrade yet — Deepack’s proprietary AI model, purpose-built for the complexity of real manufacturing environments. This isn’t just a faster model — it’s a smarter, more practical approach to industrial inspection.

The model requires as few as 100 images to train, with just 60 needing annotation, and can be deployed in minutes — not weeks. It supports continual learning, meaning it improves over time by learning from operator input and adapting to the natural variations in your production line — without needing full retrains or system overhauls:

- Previously Unseen Defects: Critically, the model can now detect and flag previously unseen defects using anomaly-based learning. This gives you a safety net for catching unexpected issues before they become expensive problems. It also includes automatic classification, giving you a clear overview of defect types and trends over time — all without the need for constant retuning.

- No Code Setup: Setup is completely no-code, allowing qualified operators to manage inspection logic, monitor performance, and update defect understanding directly from the user interface — no engineers, no programming, no external consultants.a

- Automatic Defect Classification: Once a defect is detected, the system automatically assigns it to a relevant category based on learned patterns — giving you structured insight into defect types without the need for manual tagging or sorting.

These features are designed to deliver maximum inspection performance with minimal disruption to production, ensuring that your system stays accurate, adaptive, and operator-friendly — even as new challenges and defect types emerge.

Impact:

This release sets a new standard for AI-powered quality control in manufacturing. By combining fast setup, operator-friendly workflows, and the ability to detect even unseen defects, Deepack makes it possible to deploy high-performance inspection without technical overhead:

The introduction of automatic classification means defects are not only detected — they’re organized and labeled in real time. This gives production teams complete visibility into what types of defects are occurring, how often, and under what conditions.

Most importantly, because the model is designed for continual learning from the ground up, it improves with every inspection cycle. As more data is captured and more operator input is provided, the system becomes smarter — identifying subtler defects, adjusting to new product variations, and reducing the need for manual intervention. Over time, Deepack evolves into an intelligent quality partner that scales with your production — not against it.

These updates reflect our ongoing commitment to delivering the most adaptable, accurate, and user-friendly inspection system on the market. By continuously evolving with operator feedback and real production data, Deepack ensures your quality control keeps pace with changing products, processes, and performance demands — today and into the future.

From human input to AI improvement, in real time

February 15, 2025

Version 1.4.0

Full Feedback Loop & Remote Monitoring

New Features:

Our latest release introduces operator feedback directly into the inspection workflow. If the system is unsure about a result, it can now prompt for human validation, making the AI smarter over time. We also launched a centralized dashboard with live insights and quality trends, supported by secure remote syncing for off-site monitoring and analysis.

Impact:

Deepack now becomes more accurate the more it is used — guided by the judgment of your best operators. At the same time, reporting and compliance have become easier, with access to inspection data and trends available at a glance, even from outside the factory.

Handling the rougher environment manufacturing can be subject to

July, 2024

Version 1.3.0

Environment-Robust AI & Offline Resilience

New Features:

In mid-2024, we enhanced the system’s ability to perform reliably across a variety of factory conditions, including inconsistent lighting, changes in product shape, and use of recycled materials. We also added offline capabilities so inspections continue uninterrupted, even during network outages, and improved the way our models adapt to new defect types with minimal user effort.

Impact:

These updates have significantly reduced setup time when changing product lines and ensured that Deepack performs consistently in challenging environments. This means less downtime, fewer false positives, and faster recovery after production changes.

Full coverage quality control on the production line

March 1, 2024

Version 1.2.0

Real-Time Defect Detection & Inline Inspections

New Features:

Our vision system now performs fully automated inspection inline — capturing and analyzing every unit as it moves through production. The system detects visual defects with very fast inference, with no need for manual sampling or spot checks, integrated directly in the line.

Impact:

Manufacturers can now achieve 100% visual inspection without slowing down production. This reduces the risk of defective units reaching customers and enables earlier intervention when issues arise.

Hardware & Deployment

Our vision system includes everything you need — camera, software, and interface — pre-configured for your line. Just mount, connect, and go live. No engineers needed. No complex setup.

AI Capabilities

Deepack’s AI learns normal patterns fast and flags outliers — even if the defect has never been seen before. That means better quality control, even with product variation or production with recycled materials.

Production Compliance

Every unit is tracked and logged. Whether for traceability, audits, or customer reporting — Deepack gives you full visibility into inspection performance and product quality.

Defect Escalation

Deepack can trigger I/O signals directly to machinery — stopping production, sorting out defects, or adjusting process parameters in real time. Actions are tailored through operator-defined workflows.

Explore Smarter Quality Control with Deepack

Discover how AI-driven visual inspection can reduce errors, cut costs, and adapt to your production line — without complex setups.

Book a Demo